Steering system damper

The steering damper, also known as a power steering actuator used in commercial vehicles such as trucks and buses, on the front and rear axles plays a key role, helping drivers drive vehicles with large load capacity, providing smoother and more precise maneuvering.

The basic function of the control actuator is to provide hydraulic power for the steering system of a commercial vehicles. It cooperates with the main power steering system and helps reduce the effort required to steer the vehicle, especially at low speeds and during maneuvers. Using hydraulic pressure, the cylinder strengthens the driver’s input, allowing for greater control and easy steering.

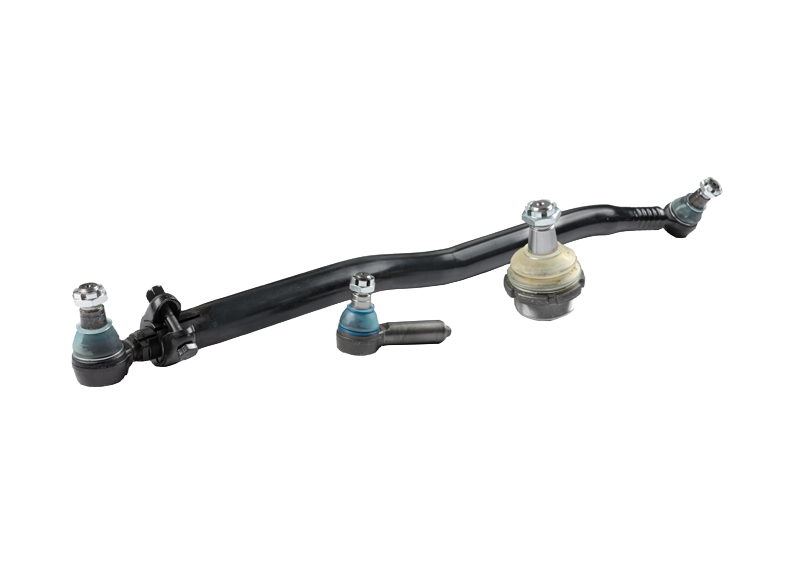

Tie rod end

These are elements whose main role is to connect the wheel knuckle to the steering system. Steering rod ends are made of flexible parts, professionally called ball joints. Thanks to the ball joints, it is possible to move the wheel suspension and also turn the steering knuckle relative to the steering gear permanently installed in the car.

Most steering components are consumable and wear out during car using. It’s hard to determine the service life for tie rod ends, as it all depends on the car model, part manufacturer, operating conditions, etc.

The most common symptoms of a defective steering part are any noises and knocks from the engine compartment. Interestigly, they are heard whether you drive a car or not. Looseness, vibration, and shaking of the steering wheel are also possible. When we notice such symptoms, the first thing to check is the tie rod ends. Their replacement is not the most difficult thing to do, but we recommend having this done by a professional workshop, due to the need for a suspension alignment.

Steering rod

The steering rod is responsible for transmitting the movement of the steering gear generated by turning the steering wheel to the wheel knuckle, i.e. its task is to properly guide the front wheels of the car. Replacement of the steering rod should never be postponed, as failure of this component while driving can have a tragic ending. Moreover, any looseness in the steering system, which is the result of wear and tear of the rod, will become an obstacle to passing the car's regular technical check-up.

When and how often a tie rod should be replaced is determined by a number of factors, such as the make of the car, the quality of the tie rod, your driving style, and the type of road surface you drive on. It’s hard to say precisely when to replace the tie rod, therefore. The steering rod itself lets you know that there is something wrong with the steering system. You can then feel, among other things, an increased looseness on the steering wheel while driving, and you can also hear a loud noise coming from under the car’s hood. The most obvious and at the same time dangerous symptom of a failure of the steering rod is that the car reacts too slowly to gentle movements of the steering wheel. There are also situations in which the car stops reacting to steering wheel movements completely. To be absolutely sure about the condition of the steering rod, you can manually check the looseness of the rod or go to a specialized diagnostic station to check the entire steering system.

Stabilizer links

Stabilizers and stabilizer links are used to reduce lateral body lean during turning.

As a result, they improve driving safety and comfort. The stabilizer is connected to the vehicle's body with connectors, which are typical components of the steering and suspension system that experience wear and tear.

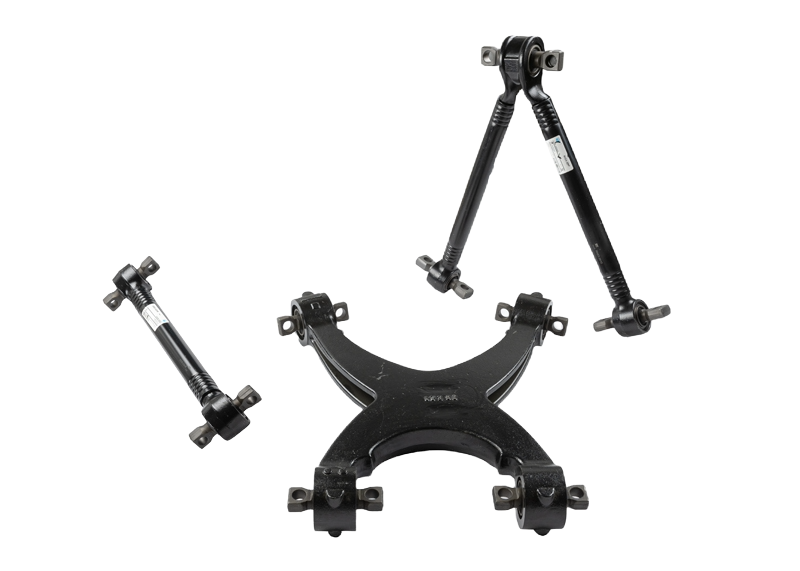

Track control arm

Trucks and buses require track control arms absorb longitudinal and lateral forces and, together with control arms and half-shafts, perform all tasks to ensure safe axle steering.

These components connect the axle longitudinally, transversely, or diagonally to the vehicle frame.

The main task of the track control arm is to keep the axle/wheels in a certain position during turning and bumps, as well as braking and speeding up. It is therefore responsible for controlling, or rather neutralizing, longitudinal (usually front axle) or transverse (rear axle) movements.