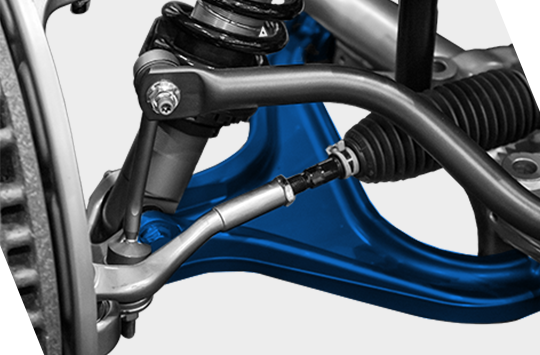

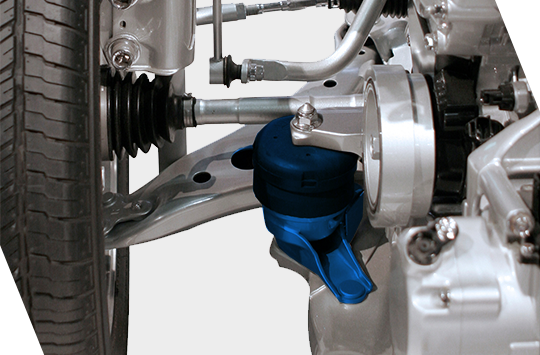

Control arms

Control arms are the main part of automotive suspension. Through a ball joint and silent blocks (track control arm) they connect the wheel with the chassis. They are guiding the wheel by keeping a knuckle in the right position. They also prevent the wheels from moving forwards and backwards, allowing the car being kept on the right track when driving. They have direct influence on the safety of driving and comfort of driving.

Classic track control arms are similar in look to triangles, but resulting from various constructions of the system, they are also sometimes a straight (longitudinal) element, the so-called trailing arms.

Depending on the technology of production, we can divide control arms into several types:

• two-piece stamped control arms,

• cast iron control arms,

• aluminium control arms, the most often applied.

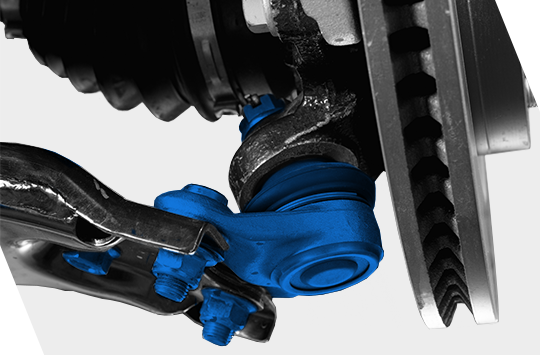

Ball joints

Integral element of almost each control arm is a ball joint, which constitutes a moving joint between a wheel (a knuckle) and the rest of the suspension. It is also responsible for control of the car, resulting in safety and comfort of driving.

Depending on the construction of a control arm, we can distinguish two types of control arms: replaceable (screwed down or pressed in) and not replaceable, fixed to the wheel track control arm permanently. When driving on uneven surfaces, great forces are applied on a ball joint, working in multiple directions, influencing the wear of the element.

That is why it is so important to choose only top-quality ball joints, designed and manufactured in line with norms and standards of the automotive market. Using REINHOCH products provides confidence in meeting required standards.

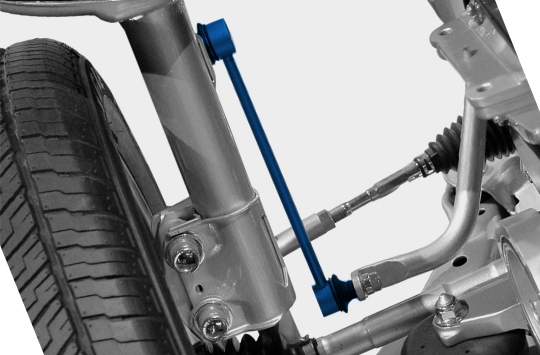

Stabilizer links

Improve handling and shock absorption, keeping the car from swaying too much as you turn, transmit forces between the chassis and bodywork - these are the main functions of stabilizer links.

Standard stabilizer links are composed of a rod and two ball joints, but we can find various constructions of the system.

Stabilizer links are a connection between the stabilizer bar and control arm or shock absorber.

Keeping the proper traction when in a curve, is crucial for the safety of each and every driver, and safety is one of the quality marks of REINHOCH products.

Steering tie rods and tie rod ends

Steering system is an integral part of a car, responsible for precision of driving direction. The system is composed of tie rods, also called tie bars and tie rod ends. Ball joints connect control arm with suspension knuckle and steering rack, so these elements have direct influence on turning the wheels.

The steering system is one of the most complicated systems used in vehicles, thanks to which it is possible to control the car and make it go in the right direction.

Next to the brake system, it is one of the most important systems in a car, that have direct influence on safety of driving.

Advanced technology used in the production process of REINHOCH tie rods and ball joints is a guarantee of reliability in every road conditions.

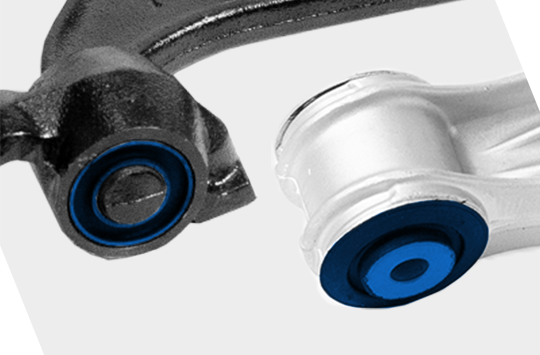

Bushings

Safety and comfort are two crucial parameters that bushings must meet. We also call them track control arm silent blocks or sleeves. These relatively small elements of the steering system take all the load of a car and transmit all the force between suspension and body of a car.

The main task of bushings is to reduce vibration which is generated when driving a car, and also make track control arms work quieter and smoother.

Rubber-metal elements are a subject of huge loads and extreme conditions of running, caused by dirt, road salt and extreme temperatures, that is why it is so important to choose the right materials for production.

Numerous endurance tests, fatigue tests and material tests are a guarantee that the metal-rubber REINHOCH products are of top quality only, resulting in comfort and safety of everyday use of a car.

Engine and transmission mounts

Engine and transmission mounts, in other words suspension elements of the powertrain of a car, have two crucial functions.

On the one hand they are a link between the powertrain and the body of a car, on the other hand, much important from the point of view of the user, they influence the comfort of driving a car, by reducing and damping vibrations, and also reducing noise and movements of the engine.

Standard engine and transmission mounts are made of metal and rubber, i.e. elements which are ageing slowly in normal course of use.

The second group are hydraulic mounts, where oil is the damping medium. That is why a very important factor, having huge influence on delaying the ageing process of material used for production is the quality, in this case of rubber and elastomer, as well as the oil.

Material used for production of REINHOCH mounts meets all the quality norms which are in line with OE standards for Automotive sector products.